Focusing on Activities to Eliminate Waste Decrease Processing Time

There are different tools in Lean you can use to identify and eliminate wasteful activities. Such as manufacturing companies hospitals and the US.

Zero Waste Lifestyle Infographic Ecogreenlove Zero Waste Lifestyle Plastic Free Life Zero Waste

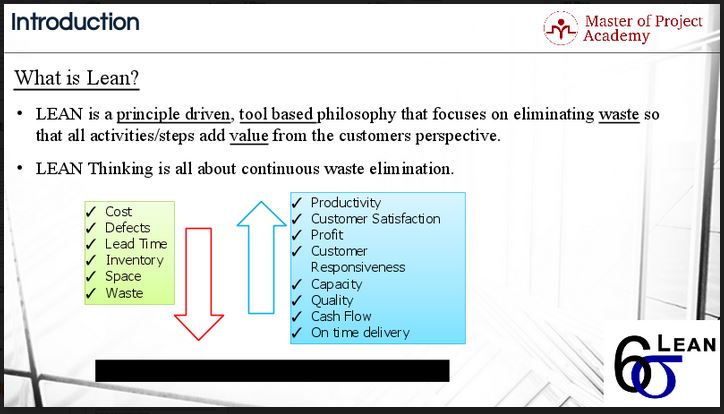

Activity-based management involves focusing on activities to.

. Involves focusing on activities to eliminate waste decrease processing time and reduce defects. The company under the JIT system will set up the machines to produce the jobs in a row from those who collect the metals at one end. The answer is simple.

In this way we can increase productivity customer satisfaction profit customer responsiveness capacity quality cash flow and on-time delivery. The work should be standardized and proper production takt time introduced. Just-In-Time JIT Method Eliminate Waste and Improve Productivity.

Eliminate waste decrease processing time and reduce defects. 61 8 830 22252. To the Vatican world leaders are stepping up their efforts to reduce food waste.

F ood waste might be finally getting the focus it deserves. Waiting in line at a store. The goal is to eliminate defects and create a disturbance-free or defect-free environment.

Focus first on waste prevention which will help eliminate waste at the source saving natural resources and energy and cutting costs. Based on comparing the performance in an organization. Learn more about PDCA tools and techniques here.

The process map should include elements such as inputs outputs activities distances organizations crossed responsibilities value added and non-value added time and activities. Start by studying the process. When analyzing and selecting your activities.

Optimize and connect all processes in such a way that the waiting time is minimized and no time is wasted. They will guide you through the work process you want to examine and show you the weak spots. Evaluate recycling and composting options to manage waste that cannot be prevented.

61 8 830 21269. Last week the. Lead times are the gaps between steps in a process or the.

A common problem-solving technique is the PDCA Plan-Do-Check-Act approach. Specific cost pool activity. Systematic approach to identifying activities with the greatest room for improvement.

When designing an activity-based costing system related activities are frequently combined to reduce the amount of detail and record-keeping cost. Improving non-bottleneck resources The company may decide to eliminate the wait times at each of the individual steps. Waiting equals wasted time and wasted time equals less profit.

Involves focusing on activities to eliminate waste decrease processing time and reduce defects. The next step is to set up problem-solving teams and enable them to reduce or eliminate the wastes. This means a relentless focus on reducing non-value adding activities.

For example Step B has a wait time of two days which results from Step B not being done fast enough. Reduce the DOWNTIME on every project. Waste from your process.

Stop contributing to non-value-add tasks. Chances are if you name your top frustrations with processes at work theyll all land in one of these categories of waste. Consider how often you waste time during one day.

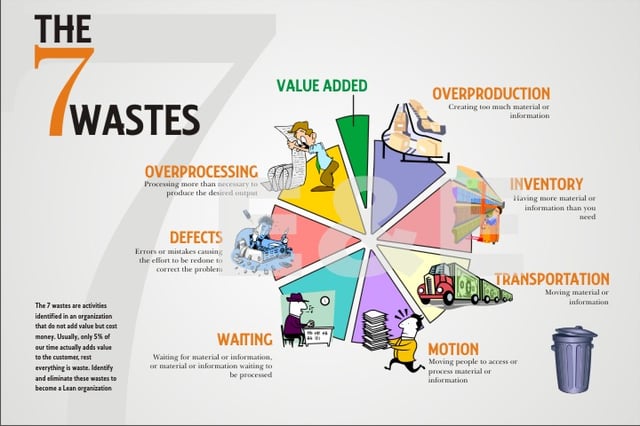

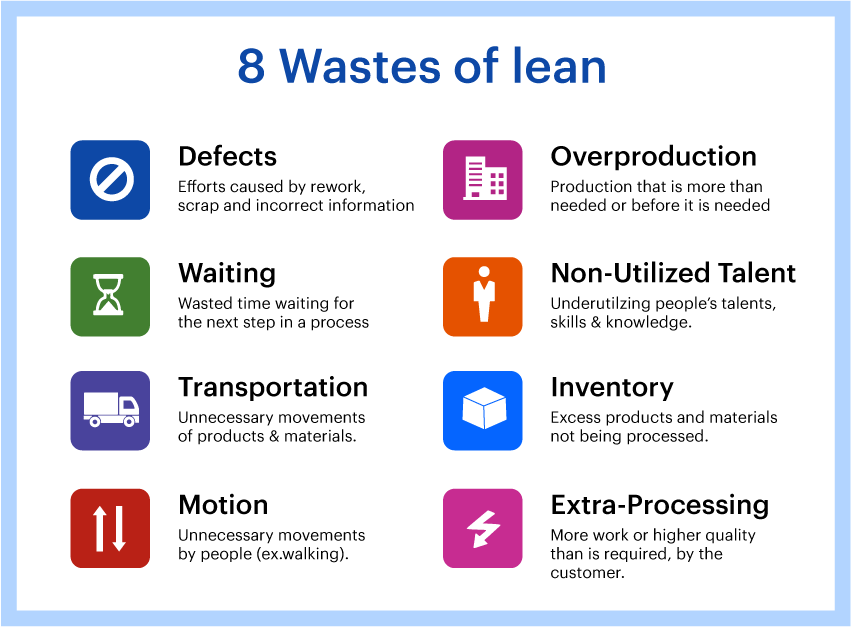

Overprocessing Investing more into a product than customer values Overprocessing means putting more into a product than is valued by the customer. It is a technique that allows you to go and see where the real work happens. The Japanese TPS system upon which Lean is.

Just-in-time or JIT means producing goods and services exactly when they are needed like for example a new company opens that is producing steering shaft for automobiles. An activity measure in activity-based costing expresses how much of an activity is carried out and it is used as the allocation base for assigning overhead costs to products and services Activity-based management involves focusing on activities to eliminate waste decrease processing time and reduce defects Ml. Implementing an activity-based costing system often results in a shift of overhead costs from.

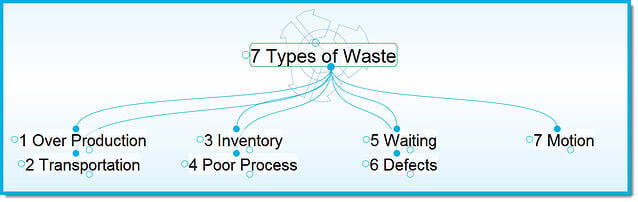

Lean Management aims to reduce cost defects lead time inventory space and waste. The paper entails background of waste types Corresponding author. By focusing on making Step B more efficient this wait time can be eliminated.

And if you cant stop then challenge yourself to reduce the total amount of non value-add tasks ie. A systematic approach to identifying the activities with the greatest room for improvement. Implement waste reduction activities best suited for your organization.

Thus an essential step in creating lean business processes is eliminating wasteful activities that eat up time and resources but provide no value to you or the customer. True False Question 2 1 pts Activity-based management involves focusing on activities to eliminate waste decrease processing time and reduce defects. This problem has been solved.

One of the first steps in applying Lean concepts on a path to operational excellence is identifying and eliminating waste. Probably the most appropriate tool for identifying Muda is the Gemba walk. Eliminate the Waste The ability to identify waste in your organization is the first step towards its elimination.

Most importantly the map should identify the primary customer of the process. Waste elimination in manufacturing is a main concept in this paper to ensure that the manufacturing sector progresses towards eco- efficient production processes and hazard-free workplace environment. True False Question 2 1.

In the old days of manufacturing this might have been called scrap. Once you can successfully identify and eliminate waste youll be well on your way to establishing. Waiting for your computer to restart Regardless of what you are waiting for in the lean philosophy wasted time is considered a significant waste.

Develop a Process Map. Again once spotted this waste is easy to get rid of simply cut out the non-value-added portions of work. Based on comparing performance between organizations.

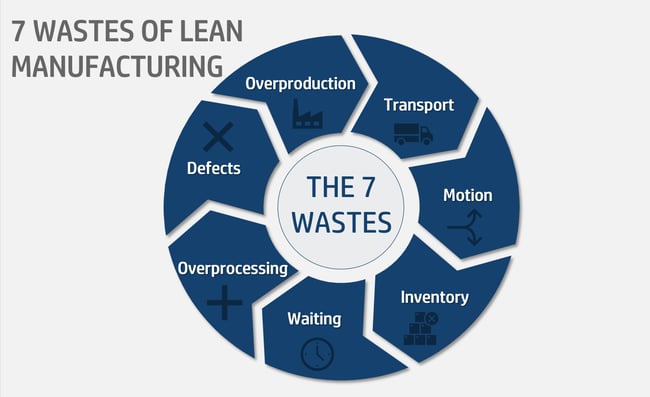

What Are The 7 Wastes That Are Killing Business Efficiency

The 7 Element Operational Excellence Management System Our Big Idea Operational Excellence Mindfulness At Work Excellence

Time Management Effective Time Management Time Management Time Management Tips

Quality Assurance Best Practices For Manufacturers Quality Assurance Best Practice Practice

Lean Tools Top 26 Lean Tools Lean Manufacturing Visual Management Lean Process Improvement

Introduction To Lean Lean Manufacturing Lean Six Sigma Technology Management

What Is Lean Management And How It Is Used To Eliminate Waste

Eliminate Non Value Added Activities In Your Organization Flevy Com Blog

8 Wastes Of Lean Manufacturing Techsolve

Eliminating 7 Types Of Waste With 5s Methodology

Identify Reduce And If Possible Eliminate 7mudas Or Nva Waste And Increase Inventory Turns And Profi Process Improvement Lean Manufacturing Lean Six Sigma

10 R S That Should Come Before Recycling Recycling Reusable Cups Low Waste Lifestyle

What Is Lean Part 6 How To Implement Lean Lean Train Blog Sales And Marketing Marketing Pins Budgeting

8 Wastes Downtime Using Lean Six Sigma Goleansixsigma Com

8 Wastes Of Lean How To Identify And Eliminate Them

7 Types Of Waste In Lean Manufacturing

8 Wastes Verspillingen Lean Lean Six Sigma Lean Sigma Lean Manufacturing

Comments

Post a Comment